Address:

No. 69 Feitian Avenue, Jiangning Airport Economic Development Zone, Nanjing, China

Phone:

+86-25-5212 2291

Email:

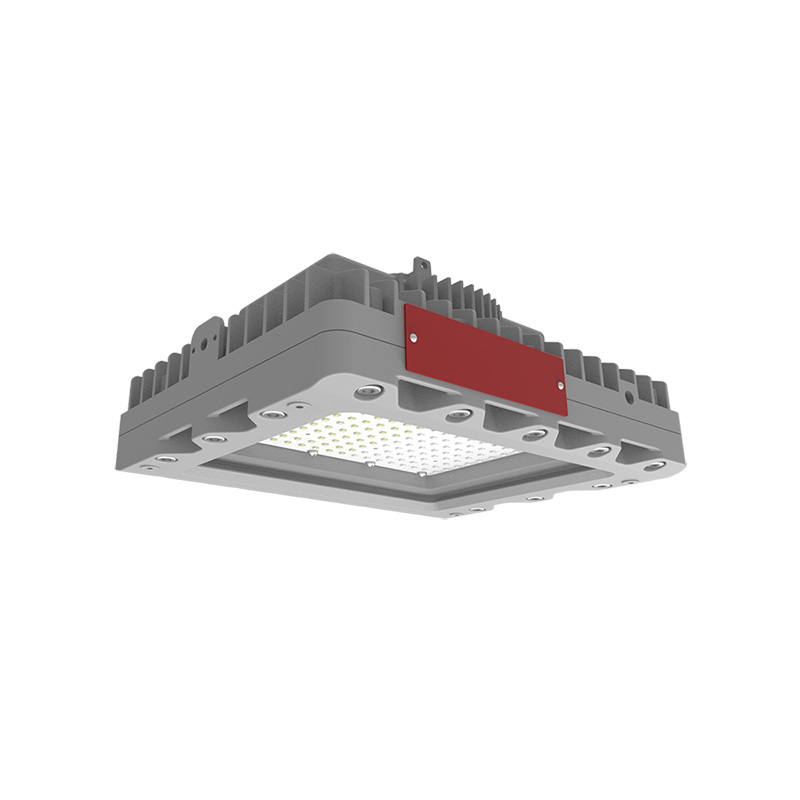

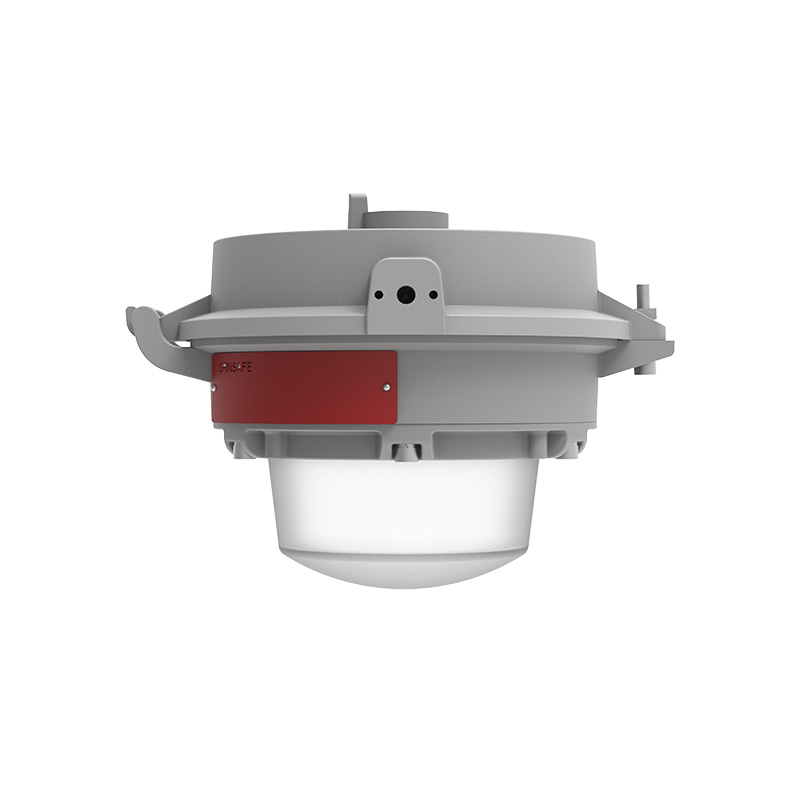

Explosion Proof Lighting

Explosion proof lighting fixtures are specially designed to prevent ignition of flammable materials in hazardous areas. Enclosed, heavy-duty construction with sealed joints and specialized lenses contain potential explosions. They meet specific safety ratings such as UL844, Atex or IECEx and utilize heat dissipation technology for cool and safe operation. Common in industries like oil and gas, explosion proof lights provide illumination without posing additional ignition risks.

Explosion proof lighting classifications

Explosion proof lighting classifications categorize fixtures for hazardous environments prone to explosions due to flammable gases, vapors, combustible dust, or ignitable fibers. National Electrical Code (NEC) in the United States classifications explosion proof / hazardous areas by class and divisions. In Europe and other parts of the world, explosion-proof lighting is classified according to a zone system defined by the ATEX (ATmosphères EXplosibles) directive or IECEx (International Electrotechnical Commission Explosive) standards.

These classifications guide the design and selection of explosion proof lighting fixtures to ensure safety and regulatory compliance.

NEC Division System Gas & Dust Groups

| Area | Group | Representative Materials |

|---|---|---|

| Class I, Division 1 & 2 |

A | Acetylene |

| B | Hydrogen, butadiene, ethylene oxide, propylene oxide and acrolein | |

| C | Ethylene, cyclopropane and ethyl ether | |

| D | Acetone, ammonia, benzene, butane, ethanol, gasoline, hexane, methane, methanol, methane, naphtha, natural gas, propane and toluene | |

| Class II, Division 1 & 2 |

E (Div. 1 only) | Combustible metal dusts: aluminum, commercial alloys and magnesium |

| F | Combustible carbonaceous dusts: carbon black, charcoal, coal and coke dusts | |

| G | Non-Conductive Dusts (flour, grain, wood, plastic, etc.) | |

| Class III, Division 1 & 2 |

None | Ignitible fibers/flyings, such as cotton lint, flax & rayon |

NEC & IEC Zone System Gas & Dust Groups

| Area | Group | Representative Materials | Equivalent to NEC |

|---|---|---|---|

| Zone 0, 1 & 2 | II C | Acetylene & Hydrogen | Class I, Groups A and B |

| II B + H2 | Hydrogen | Class I, Group B | |

| II B | Ethylene | Class I, Group C | |

| II A | Propane | Class I, Group D | |

| Zone 20, 21 & 22 | III C | Conductive dusts, such as magnesium | Glass II, Group E |

| III B | Non-conductive dusts, such as flour, grain, wood & plastic | Class II, Groups F and G | |

| III A | Ignitible fibers/flyings, such as cotton lint, flax & rayon | Class III | |

| Mines susceptible to firedamp | I (IEC only) | Methane |